AREAS OF APPLICATION

GEOLOGY AND MINERALOGY

me

CERAMICS

MATERIAL RESEARCH

MECHANICAL ALLOYING

NANOTECHNOLOGY

PHARMACEUTICALS

CHEMISTRY

BIOLOGY

SAMPLE PREPARATION FOR ANALYSIS

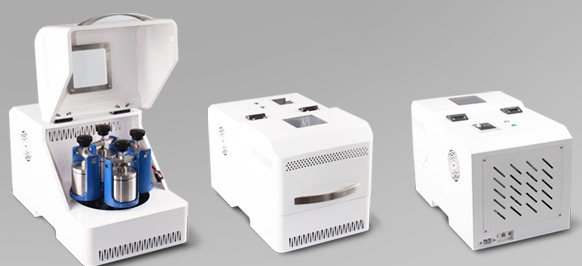

| Selling Units: | Single item |

| Single package size: | 57X37X42 cm |

| Single gross weight: | 45.0 KG |

| Package Type: | Planetary Ball Mill Package: (1) stretch film (2) styrofoam (3) plywood case |

AREAS OF APPLICATION

GEOLOGY AND MINERALOGY

METALLURGY

CERAMICS

MATERIAL RESEARCH

MECHANICAL ALLOYING

NANOTECHNOLOGY

PHARMACEUTICALS

CHEMISTRY

BIOLOGY

SAMPLE PREPARATION FOR ANALYSIS

|

Working Principle |

|

|

Comminution according to the Planetary Principle The comminution of the material to be ground takes place primarily through the high-energy impact of grinding balls. To achieve this, the grinding jar, containing the material to be ground and grinding balls, rotates around its own axis on a main disk whilst rotating rapidly in the opposite direction. At a certain speed, the centrifugal force causes the ground sample material and grinding balls to separate from the inner wall of the grinding jar. The grinding balls then cross the jar at high speed and further grind the sample material by impact against the opposite jar wall. In addition, impact between the balls themselves on the sample material adds to the size reduction process. |

|

|

Ideal For |

|

Pearl, ginseng, dendrobium candidum, tablet, medicament, liquorice, coke, coal, glass fibrous, paper, chip, polymer, pigment, metallic oxide, iron ore, iron powder, bone,alumina ceramic, gypsum, quartz, mineral, graphite, concrete, soil, alloy, cement clinker,wood, slag, tobacco, catalyst, sewage sludge. Planetary mill is universally applicable for quick dry or wet grinding of inorganic and organic samples for analysis, quality control, materials testing and mechanical alloying. In synthesis, planetary mills can be used for mixing and homogenisation of dry samples, of emulsions and of pastes. |

|

Features of Planetary Ball Mills |

|

Grinding chamber with automatic LED lighting Fast comminution of laboratory samples with up to 800 rpm Simultaneous processing of up to 8 samples 4 working stations Useful capacity up to 4*500ml Programmable grinding and pause times and grinding sequences – for short-time operation adjustable down to the second High uniformity and excellent repeatability Smaller grinding bowls also possible with an adapter Reversing function Extensive accessories for simplifying your daily work Cooling of the grinding chamber with a built-in fan for long grinding times Low noise with high polymer gears and grease lubrication |

|

Technical Data of Planetary Ball Mills |

|

|

Optimal for material type: |

medium-hard, soft, brittle, tough, moist |

|

Item No.: |

CHL-IP4 |

|

Max. feed size: |

5mm |

|

Final fineness: |

<100nm |

|

Min. sample quantity: |

10ml |

|

Max. sample quantity: |

180ml |

|

Rotational speed (disk): |

50-450r/min |

|

Rotational speed (jars): |

100-900r/min |

|

Transmission ratio: |

1:-2 |

|

Transmission standard: |

CE |

|

Grinding modes: |

16 modes programmable |

|

Grinding tools: |

grinding jars and grinding balls |

|

Bi-direction grinding: |

yes |

|

Continuously grinding |

00:01:00 - 99:59:59 |

|

Paused interval: |

00:01:00 - 99:59:59 |

|

Emergency stop: |

yes |

|

Power off memory: |

yes |

|

Overload protection |

Yes |

|

Milling chamber lighting: |

automatic LED lighting, 220V, 18W |

|

Number of milling samples: |

4 simultaneously |

|

Materials of the grinding jars: |

SS304, SS316, nylon, PTFE, agate, zirconia, alumina, PU, WC |

|

Number of working stations: |

4 |

|

Ball mill type: |

vertical |

|

Compatible grinding jars: |

50ml / 100ml |

|

Materials of milling balls: |

SS, agate, zirconia, alumina, nylon, PTFE |

|

Grinding ball diameter: |

3/5/10/15/20mm |

|

Compatibal ball weight |

40-200g |

|

Grinding process: |

dry /wet grinding |

|

Vacuum grinding: |

yes |

|

Low temperature grinding: |

yes |

|

Grinding in inert gas: |

yes |

|

Temperature detection: |

yes ( special accessories) |

|

Pressure detection: |

yes ( special accessories) |

|

Electrical details: |

100-120V/200-240V AC ,50-60Hz, 250W |

|

Plug types: |

GB/EU/US/UK standard |

|

Net weight: |

35kg |

|

Dimensions (W x D x H): |

500*300*350mm |

|

Noise level: |

60dB |

|

IP rank: |

IP60 |

|

Product standard: |

CE |

|

Patent: |

design patent/ noise improve patent |

|

Accessories: |

user manual, warranty card |

|

Material Data for Grinding Jars/Balls |

||||

|

Material |

Main component |

Density (g/cm3) |

Abrasion resistance |

Use for material to be ground |

|

Agate |

SiO2 |

2.65 |

Good |

Soft to medium-hard samples |

|

Sintered corundum |

Al2O3 |

3.8 |

Fairly good |

Medium-hard, fibrous samples |

|

Silicon nitride |

Si3N4 |

3.25 |

Excellent |

Abrasive samples, iron-free milling |

|

Zirconium oxide |

ZrO2 |

5.7 |

Very good |

Fibrous, abrasive samples |

|

Stainless steel |

Fe –Cr –Ni |

7.8 |

Fairly good |

Medium-hard, brittle samples |

|

Tempered steel |

Fe –Cr |

7.65 |

Good |

Hard, brittle samples |

|

Tungsten carbide |

WC |

14.95 |

Very good |

Hard, abrasive samples |

|

Polypropylene disposable jar |

MC/PA/PTFE/PU/HDPE/PP |

** |

Good |

For homogenisation |

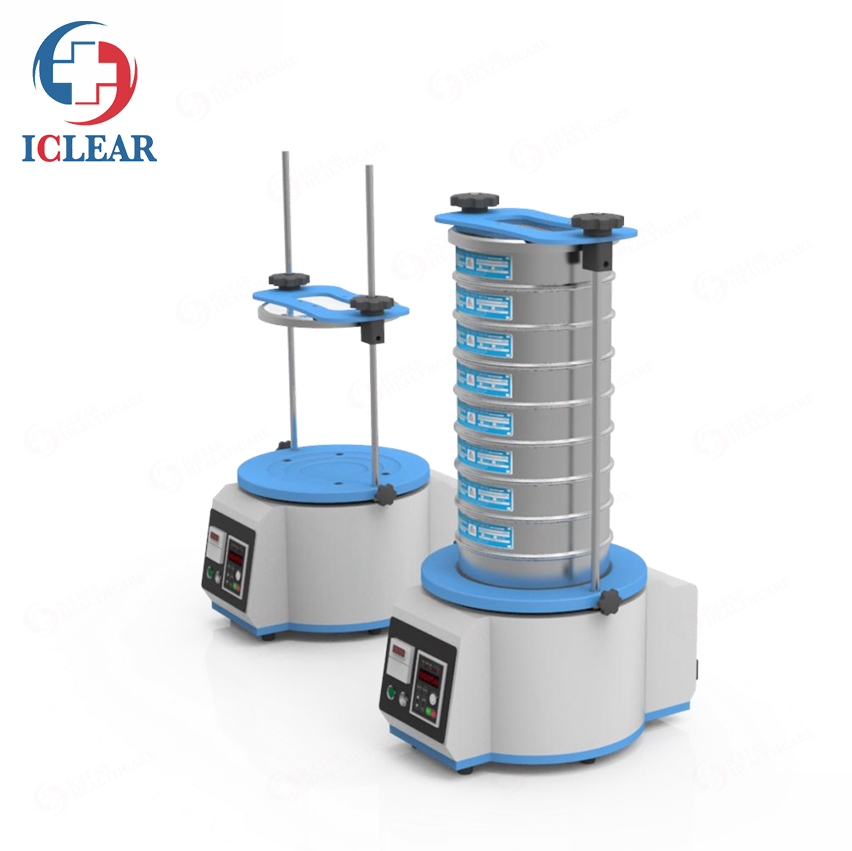

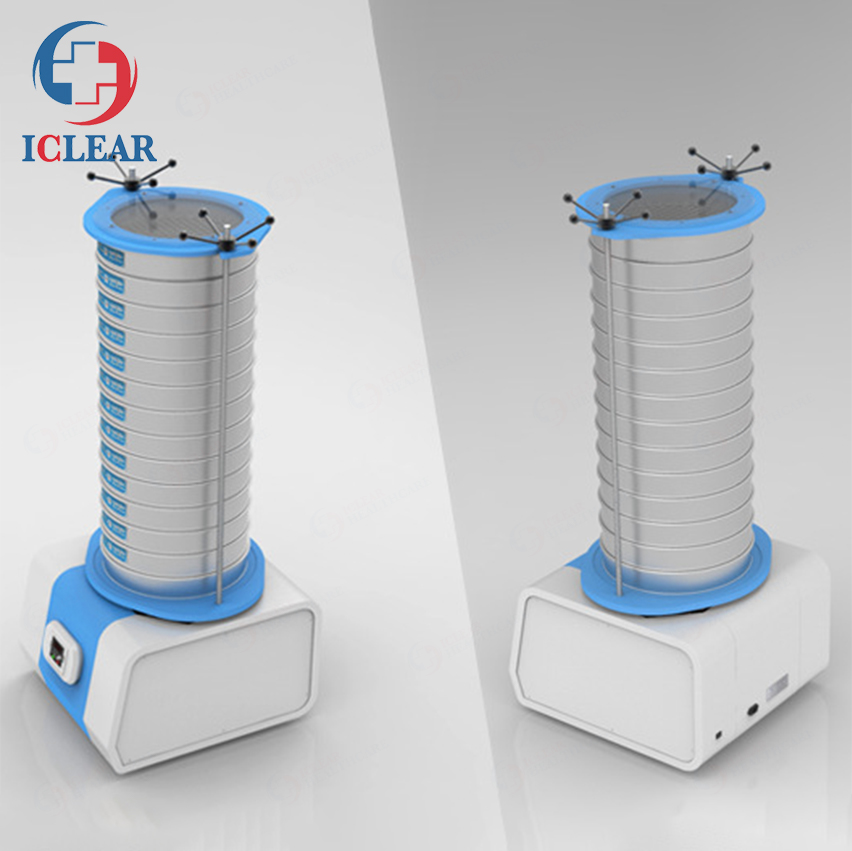

Lab Vibrating Disc Grinder Disc/Cup Vibratory Grinding Mill...

Classic 3kg Lab 3D Vibratory Sieve Shaker for Dry and Wet Sample...

3D Mechanical Vibrating Lab bulk dried samples Sieving Machine...

Economic High Precision 200mm 8 Inches Lab Sieve Shakers...